Mechanics of Machinery

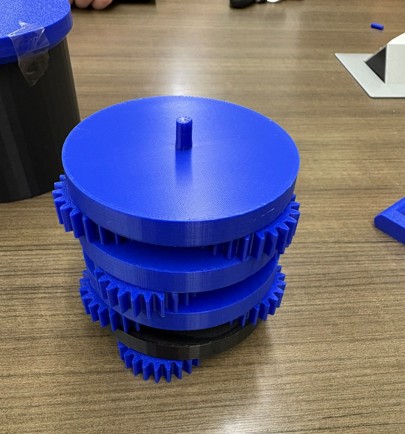

This course focuses on the kinematic and dynamic analysis of mechanisms and the design of cams, gear trains, and linkages for motion and force transmission. Topics include:

- Kinematic analysis of positions, velocities, and accelerations

- Cam system design for specified motion

- Gear train analysis for speed ratios

- Force analysis in gears and linkages

- Application of computational tools such as SolidWorks and Python for simulation and analysis

Through a combination of analytical methods, software tools, and a team-based final design project, students gain a deep understanding of how mechanisms function and how they can be optimized for performance, reliability, and practical applications.

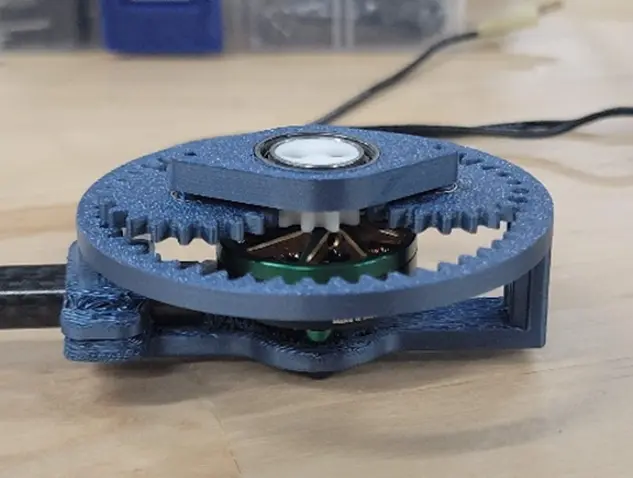

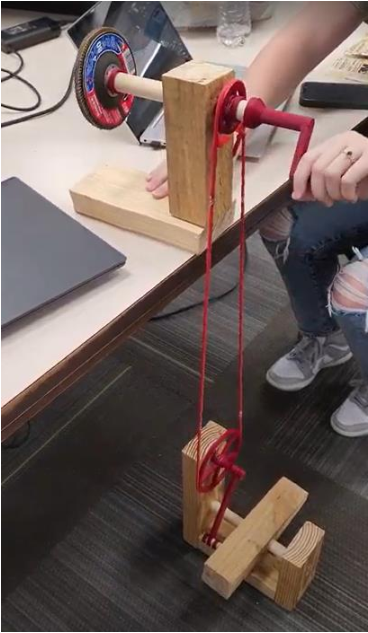

Representative student projects include the Design, Analysis, and Fabrication are demonstrated as:

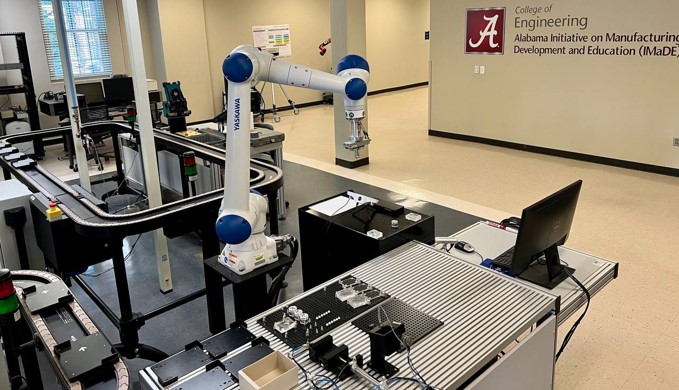

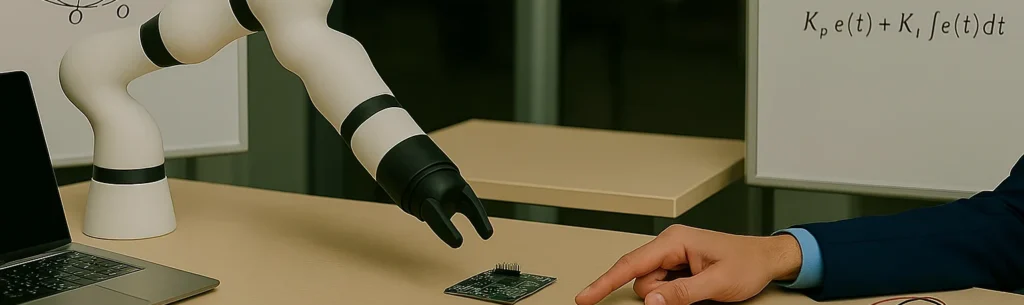

Robotics and Automation Courses

These modular courses cover the fundamentals and advanced aspects of robotics, automation, and industrial systems, with emphasis on design, control, and integration. Students gain hands-on experience with hardware, software, and simulation tools, preparing them for real-world challenges in robotics and advanced manufacturing.

Basics of Robotics

Students are introduced to the foundations of robotics, including:

- The world of robotics and its applications

- Programming fundamentals for robot control

- Sensors and actuators used in robotic systems

- Degrees of freedom and kinematic concepts

- Robot inputs, outputs, and end effector design

Basics and Advanced PLC (Programmable Logic Controllers)

Students learn to:

- Write programs for sequential and continuous PLC-controlled processes

- Identify and work with PLC hardware components

- Apply skills in projects such as automated sorting on a production line

Automation and Materials Handling

Hands-on experience with robotic automation through SCORBASE software,

where students:

- Write, edit, and run control programs

- Send and receive input/output signals between robots and software

- Apply concepts to automation and materials handling scenarios

Robotic Welding

An introduction to robotic welding, combining theory and practice:

- Fundamentals of welding and automated welding systems

- Common welding problems and their solutions

- Welding safety training through virtual reality environments

Industrial Automation with Robotics

Using Siemens Tecnomatix RobotExpert, students:

- Integrate kinematics with CAD files to simulate robotic tasks

- Design and test automated solutions for real-world manufacturing processes

- Explore industry-level applications of robotic automation

Flexible Manufacturing Systems (FMS)

Students gain exposure to system-level integration by:

- Designing, programming, and simulating an FMS work cell

- Creating full simulations of manufacturing operations

- Developing strategies for efficient, flexible production systems

Through these courses, students engage in analysis, programming, and immersive training with cutting-edge tools such as virtual reality and industrial software. Representative student projects and assignments include: